Highlights

- The workers' movement data is gathered through edge devices, IP cameras, and AI Box

- Supervised Learning, In-house Teaching data is used alerts when positions that do not occur in usual work are detected, such as a situation when a worker has fallen or is injured.

- Detection of abnormalities in position, posture, number of workers, and moving area. Entry to the backside of the manufacturing line, higher or lower moving speed of workers, and detection of dollies or containers left out in working areas.

- Detection of an abnormality such as unsupervised staff. By learning patterns of stored data over months, one can use pre-defined posture types and coordinate values for the detection of new data as an abnormality.

- Development of notification rules. Defining rules for each abnormality creates an immediate notification of such abnormality. One can use appropriate communicationchannels such as email and SMS, and smartphone apps for each notification.

- Enabling check records of anomaly detection on a dashboard.

Accidents seem to be an ongoing and sometimes fatal issue throughout workplaces, whether on the production floor, building sites, or warehouses. When you add in the pandemic and the rising frequency and severity of natural disasters, workplace and population safety become really challenging. Employers are concerned about workplace health and safety and interested in what applied machine learning can offer.

What is a Safer Workplace?

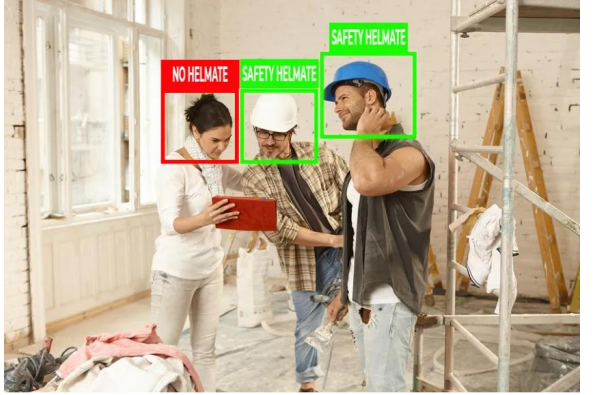

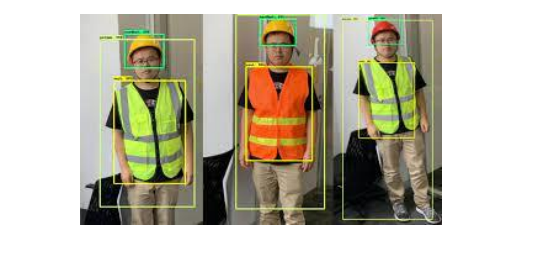

A safe workplace can be based on generations of management best practices combined with a clear understanding of what hazards exist. The key is to match job tasks with worker capabilities, to allow employees to work at the safe level they are trained and licensed to perform. Improving Worker Safety and Quality Assurance with CameraBased AI Detection System in Manufacturing FactoriesSolutionOverview

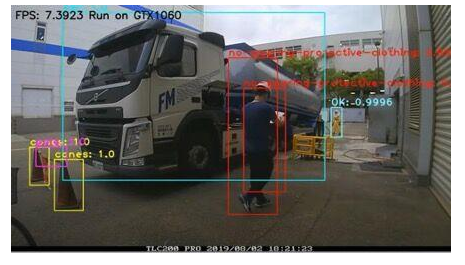

Using Edge devices, IP cameras and AI Box, the solution observes workers' movements within a factory and detects laborers who have collapsed or are injured or ill. The solution monitors suspicious acts such as unauthorized entry or work interruption. Once the status is judged abnormal, data is sent to AI Box and a supervisor is alerted

Solution Details: In manufacturing plants, a review of the labor environment is as important as the efficiency of the manufacturing process. In the food industry, a high level of labor motivation is as important as preventing contamination with foreign matters and with drugs by malicious persons. In such circumstances recognizing individual persons are very difficult because the uniforms, caps, masks are worn.

This system is able to identify individual persons by ID number given by the system to all the laborers at their entry to the plant. Which works on edge devices, like IP cameras and an AI Box set up near production lines, detects a worker’s skeleton and posture in a factory.

- Detect unusual situation in a factory immediately, in case a worker collapses or

- unauthorized entry or work interruption takes place. Find causes for repetitive drops of products.

- Monitor the production process for making continuous improvement and positioning of the process.

- Data acquisition for replacing with robotics.

- Rapid detection of contamination or failure by checking for workers' unusual behaviors.

Solutin Benefits

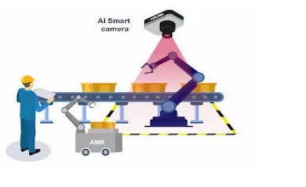

How Smart Cameras Help Solve Some of Manufacturing’s Biggest Issues?

Artificial intelligence-enabled smart cameras can be used to improve safety, quality, and operator efficiency.Artificial intelligence-enabled smart cameras can be used to improve safety, quality, and operator efficiency. Manufacturers can benefit from AI machine vision technologies by increasing uptime, leverage preventive maintenance and more

Learning Objectives Manufacturers that leverage real-time AI machine vision data can improve manufacturing operations in many ways. These tasks used to be done manually, but can now be automated. The AI vision system can improve worker safety and provide alerts of potential hazards or dangers to the worker. In traditional industrial and manufacturing environments, monitoring worker safety, enhancing operator efficiency and improving quality inspection were physical tasks. Today, AI-enabled machine vision technologies replace many of these inefficient, laborintensive operations for greater reliability, safety, and efficiency. By deploying AI smart cameras, further performance improvements are possible since the data used to empower AI machine vision comes from the camera itself.

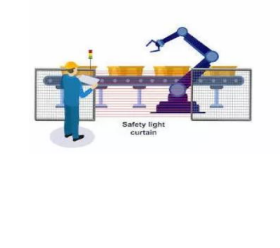

AI for smart worker safety Fatalities in industrial settings are not unheard of. When evaluating worker safety, facilities also must consider non-fatal work-related injuries. In addition to the emotional trauma, there is often a financial consideration to take into account. Industrial and manufacturing sites traditionally use human supervision and light curtains for ensuring worker safety. However, human supervisors, who cannot be everywhere and see everything, are fallible and safety light curtains have their inherent limitations.

Smart refueling with AI vision

When a fuel truck arrives at a manufacturing facility, it introduces the potential for multiple safety issues smart AI vision can resolve. First of all, the truck may roll if the brake is not applied correctly or fails. Training the AI machine vision system to monitor the truck for movement enables it to raise an immediate alarm should the status change. Facilities also must consider the operator’s location during the refueling process because there are different types of zoning breaches. It is critical to ensure that all workers on-site understand that there are safety risks.

Conclusion

The best way to build safer workplaces is by installing video surveillance systems. Advanced video surveillance technology can enhance the quality of in-house security personnel, thereby improving the standard of work at every level. Computer vision has an increasing role in managing working environments. For example, we’ve seen it deployed at factories to monitor dangerous gasses, inside a tunnel to track movement in real-time, and at a factory dealing with hazardous chemicals. We use industry leading computer vision methods which allow us to infer a person’s demography, activity, and intent in real-time

We Are Customers

--